竹材表面金属涂层的高效热喷涂制备方法

编号

lyqk011193

中文标题

竹材表面金属涂层的高效热喷涂制备方法

作者单位

南京林业大学机械电子工程学院 南京 210037

期刊名称

世界竹藤通讯

年份

2023

卷号

21

期号

5

栏目名称

学术园地

中文摘要

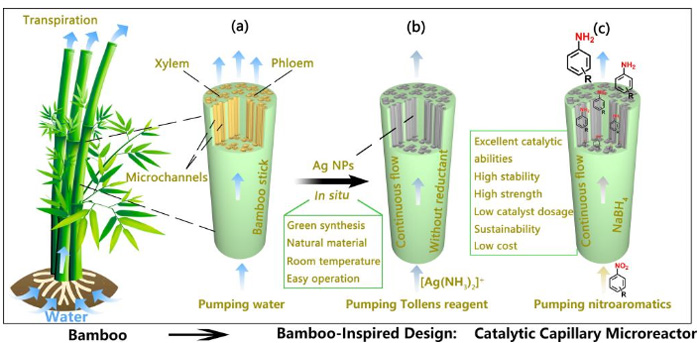

在竹材表面制备出金属涂层,可赋予竹材耐蚀、耐磨、导电、导热、电磁屏蔽等特殊功能,形成高附加值的竹基金属复合材料。然而,如何打破竹材和金属材料之间的天然壁垒、实现高效率涂层制备一直是亟待解决的难题。文章提出利用热喷涂技术在竹材表面进行金属涂层高效制备的新思路。以竹材为基体、以耐蚀Fe-Cr合金为涂层材料,采用电弧热喷涂方法开展了实验研究。结果表明:电弧热喷涂加工方法可成功在竹材表面制备出Fe-Cr合金涂层;当喷涂电压30 V、喷涂电流100 A时,涂层制备效率可达9 g/min,涂层表面粗糙度约为Ra 3.0 μm,平均厚度超过100 μm;控制热喷涂的加工时间和输入能量,可有效降低竹材表面烧蚀概率;尽管金属材料和竹材之间存在着天然不相容性,但是二者之间可通过咬合界面形成结合力,促使金属涂层稳定附着于竹材表面。

基金项目

江苏省农业科技自主创新资金项目(CX(20)3067)。

英文标题

Preparation Method of High-Efficiency Thermal Sprayed Metal Coatings on Bamboo Surface

作者英文名

Chen Jipeng, Wang Ji, Wang Linghao, Zhou Hongping

单位英文名

School of Mechanical and Electronic Engineering, Nanjing Forestry University, Nanjing 210037, China

英文摘要

Preparing a metal coating on bamboo surface can endow bamboo with special functions such as corrosion resistance, wear resistance, conductivity, thermal conductivity, and electromagnetic shielding, forming a value-added bamboo-based metal composite material. However, breaking the natural barrier between bamboo and metal materials to achieve high-efficiency coating preparation has always been a problem to be solved. In this paper, thermal spraying technology is used for the preparation of metal coating on bamboo surface. Arc thermal spraying preparation experiments are conducted using Fe-Cr alloys as the coating materials. The results show that Fe-Cr alloy coating can be successfully prepared on the bamboo surface with arc spraying method. When the spraying voltage is 30 V and the spraying current is 100 A, the coating preparation efficiency reaches 9 g/min, and the surface roughness of the coating is about Ra3.0 μ m with an average thickness exceeding 100 μm. Controlling the processing time and input energy of thermal spraying can effectively reduce the ablation probability of bamboo surface. Although there is a natural incompatibility between metal materials and bamboo, the bonding force can be formed through the biting interface, which promotes the stable adhesion of the metal coating to the surface of bamboo.

英文关键词

bamboo;metal;bamboo-based metal composites;thermal spraying;bonding interface

起始页码

12

截止页码

18

作者简介

陈吉朋,工学博士,副教授,硕士生导师,主要从事先进制造技术和林业机械装备的教学和研究工作。E-mail:cjp@njfu.edu.cn。

DOI

10.12168/sjzttx.2023.07.27.001

参考文献

[1] 苗虎, 王晓欢, 费本华, 等. 竹业机械技术现状与发展对策[J]. 世界竹藤通讯, 2022, 20(2):6-11.

[2] RAO F, ZHU X, ZHANG Y, et al. Water resistance and mechanical properties of bamboo scrimber composite made from different units of Bambusa chungii as a function of resin content[J]. Construction and Building Materials, 2022, 335:127250. DOI:10.1016/j.conbuildmat.2022.127250.

[3] CHEN M, YE L, SEMPLE K, et al. A new protocol for rapid assessment of bond durability of bio-based pipes:bamboo winding composite pipe as a case study[J]. European Journal of Wood and Wood Products, 2022, 80:947-959.

[4] ZHANG G X, CHEN Y M, CHEN Y J, et al. Activated biomass carbon made from bamboo as electrode material for supercapacitors[J]. Materials Research Bulletin, 2018, 102:391-398.

[5] ZHANG X P, ZHONG Y, XIA X H, et al. Metal-embedded porous graphitic carbon fibers fabricated from bamboo sticks as a novel cathode for lithium-sulfur batteries[J]. ACS Applied Materials & Interfaces, 2018, 10(16):13598-13605.

[6] LI Z, CHEN C, MI R, et al. A strong, tough, and scalable structural material from fast-growing bamboo[J]. Advanced Materials, 2020, 32(10):1906308. DOI:10.1002/adma.201906308.

[7] WANG X, SHAN S, SHI S Q, et al. Optically transparent bamboo with high strength and low thermal conductivity[J]. ACS Applied Materials & Interfaces, 2020, 13(1):1662-1669.

[8] WANG F, WANG L, WU H, et al. A lotus-leaf-like SiO2 superhydrophobic bamboo surface based on soft lithography[J]. Colloids and Surfaces A:Physicochemical and Engineering Aspects, 2017, 520:834-840.

[9] BAO W, LIANG D, ZHANG M, et al. Durable, high conductivity, superhydrophobicity bamboo timber surface for nanoimprint stamps[J]. Progress in Natural Science:Materials International, 2017, 27(6):669-673.

[10] LIN Q, GAO R, LI D, et al. Bamboo-inspired cell-scale assembly for energy device applications[J]. npj Flexible Electronics, 2022, 6(1):1-8.

[11] GAO Q, HU J, HUANG Y, et al. Facile preparation of multifunctional bamboo with superhydrophobic, conductive, and flame-retardant properties[J]. Industrial Crops and Products, 2022, 188:115676. DOI:10.1016/j.indcrop.2022.115676.

[12] WANG D, HU C, GU J, et al. Bamboo surface coated with polymethylsilsesquioxane/Cu-containing nanoparticles (PMS/CuNP) xerogel for superhydrophobic and anti-mildew performance[J]. Journal of Wood Science, 2020, 66:1-8.

[13] WANG J, WANG Z, YU H, et al. Designing a novel type of multifunctional bamboo surface based on an RGO/Ag coating[J]. Arabian Journal of Chemistry, 2022, 15(12):104332. DOI:10.1016/j.arabjc.2022.104332.

[14] DEVARAj S, McDONALD A, CHANDRA S. Metallization of porous polyethylene using a wire-arc spray process for heat transfer applications[J]. Journal of Thermal Spray Technology, 2021, 30(1):145-156.

[15] YOSHIMURA T, TAKAHASHI M. Biological resistance of Zn-Al metal-coated wood[J]. Journal of Wood Science, 2000, 46(4):327-330.

[16] 陈吉朋, 张雨秋, 王计安, 等. 一种竹基金属复合材料及其制备方法:202310222533.3[P]. 2023-06-13.

[17] TEJERO-MARTIN D, REZVANI RAD M, McDONALD A, et al. Beyond traditional coatings:a review on thermal-sprayed functional and smart coatings[J]. Journal of Thermal Spray Technology, 2019, 28(4):598-644.

[18] GERULLIS S, PFUCH A, SPANGE S, et al. Thin antimicrobial silver, copper or zinc containing SiOx films on wood polymer composites (WPC) applied by atmospheric pressure plasma chemical vapour deposition (APCVD) and sol-gel technology[J]. European Journal of Wood and Wood Products, 2018, 76(1):229-241.

[19] JHU Y S, HUNG K C, XU J W, et al. Effects of acetylation on the thermal decomposition kinetics of makino bamboo fibers[J]. Wood Science and Technology, 2019, 53(4):873-887.

[20] ZHANG B, CHENG J, LIANG X. Effects of Cr and Mo additions on formation and mechanical properties of Arc-sprayed FeBSiNb-based glassy coatings[J]. Journal of Non-Crystalline Solids, 2018, 499:245-251.

[21] BOXMAN R L, GOLDSMITH S. Macroparticle contamination in cathodic arc coatings:generation, transport and control[J]. Surface and Coatings Technology, 1992, 52(1):39-50.

[22] NEWBERY A P, GRANT P S, NEISER R A. The velocity and temperature of steel droplets during electric arc spraying[J]. Surface and Coatings Technology, 2005, 195(1):91-101.

[23] HAUER M, HENKEL K M, KREBS S, et al. Alternative gas mixtures in arc spraying:a chance to improve coating properties and residual stress states[J]. Journal of Thermal Spray Technology, 2018, 27(1):106-118.

[24] WANG R, LI Z, ZHANG Z, et al. Influence of temperature on the mechanical properties of engineered bamboo laminate[J]. Construction and Building Materials, 2022, 341:127825. DOI:10.1016/j.conbuildmat.2022.127825.

[25] WAGNER N. Effect of process parameters on twin wire arc sprayed steel coatings[J]. Journal of Materials Engineering and Performance, 2021, 30(9):6650-6655.

[26] TIAN H, WANG C, GUO M, et al. Phase composition and formation mechanisms of a high-velocity electric arc-sprayed FeNiCrAl coating[J]. Journal of Alloys and Compounds, 2018, 769:998-1006.

PDF全文

浏览全文

-

相关记录

更多

- 竹材物理力学性质影响因素研究进展 2024

- 竹节结构及力学性能研究现状 2024

- 竹材定向刨花板生产与应用现状及前景 2023

- 不同比例竹源废弃物混合发酵对有机肥质量的影响 2023

- 浙江临安笋、竹加工业现状与发展对策 2023

- 竹材集材关键技术装备研究现状 2023

打印

打印